Circular Knitting Machine

Kinda VFD applied in circular knitting machine (textile)

1, Load feature

Circular Knitting Machine is widely used in the textile industry, it’s usually started by external signal, speed is

controlled by external analog signal.

The running speed is high, start torque is high, and also the system always needs fast stop.

2, Requests for AC Drive (VFD)

(1) Big output torque at low frequency.

(2) Fast response during start.

(3) Running smoothly during running.

(4) Stop smoothly and accurately, without reverse.

3, Onsite picture

3, Onsite picture

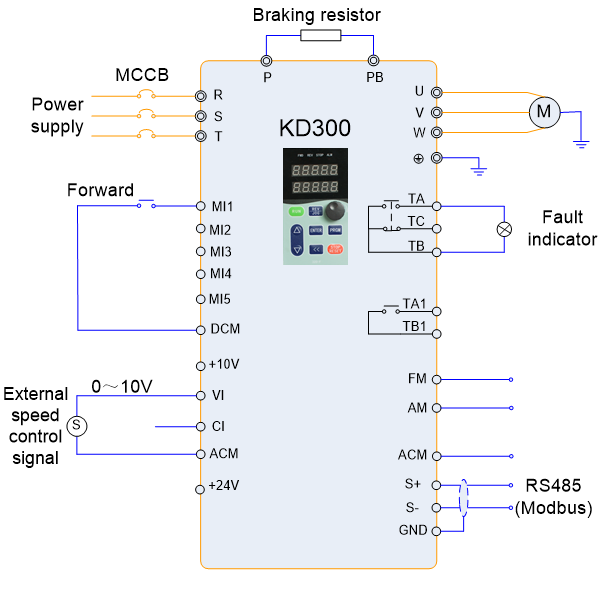

4, Typical wiring diagram

5, Parameters setting list

| No. | Function codes | Default | Setting value | Explanation |

| 1 | F0-02 | 0 | 1 | External start / stop signal |

| 2 | FO-03 | 1 | 2 | The speed is controlled by external 0~10V signal |

| 3 | F0-10 | 50 | 80 | Maximum frequency |

| 4 | F0-12 | 50 | 80 | Frequency upper limit |

| 5 | F0-17 | Model depend | 5s | Acceleration time (adjustable) |

| 6 | F0-18 | Model depend | 0.5s | Deceleration tiem (adjustable) |

| 7 | F1-17 | 0 | 2 | S-curve ACC / DEC B |

| 8 | F1-11 | 0 | 1.5 | DC braking start frequency while stopping |

| 9 | F1-13 | 0 | 60 | DC braking current while stopping |

| 10 | F1-14 | 0 | 0.8s | DC braking time while stopping |

| 11 | F6-02 | 2 | 2 | Fault output |

| 12 | F8-13 | 0 | 1 | Reverse forbidden |

(1) Maintenance regularly, pay attention to ventilation, heat sink, and dust prevention.

(2) Before running the machine, remove the load and adjust the motor running direction to be correct.

(3) Pay special attention on the reversal while stopping, a slight reverse will cause damage to the dial, customer can

change the S-curve mode or fine tuning the DC braking parameters to remove the reversal.

change the S-curve mode or fine tuning the DC braking parameters to remove the reversal.